Cookies help us deliver our services. By using our services, you agree to our use of cookies.

Learn more

X

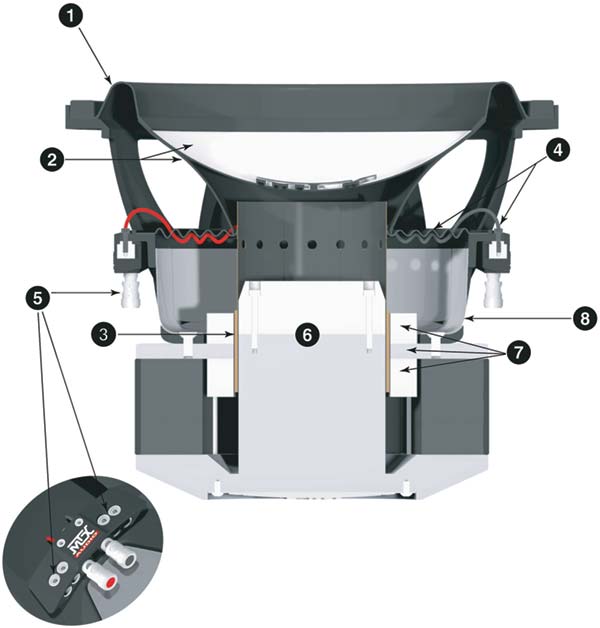

Thunder T9500 2003 Sub Archive

2003 Generation Thunder 9500 Subwoofers

- Models T9510, T9512, T9515

T9500 2003 Generation Tech Data Reports

- T9515-44 15" Dual 4 Ω Car Subwoofer

- T9515-04 15" 4 Ω Car Subwoofer

- T9512-44 12" Dual 4 Ω Car Subwoofer

- T9512-04 12" 4 Ω Car Subwoofer

- T9510-44 10" Dual 4 Ω Car Subwoofer

- T9510-04 10" 4 Ω Car Subwoofer

Thunder 9500 2003 Generation Subwoofer Specifications

Thunder 9515 Subwoofer Specifications |

||

| Model | T9515-44 | T9515-04 |

| Description | 15" Subwoofer | 15" Subwoofer |

| Impedance | Dual 4 Ω | 4 Ω |

| RMS Power (Watts) | 1,000 | 1,000 |

| Rec. RMS Amplifier Power (Watts) |

500 - 1,000 | 500 - 1,000 |

| Sensitivity | 90.38dB | 90.38dB |

| Voice Coil | 4" | 4" |

| Magnet Weight (oz.) | 260 | 260 |

| Mounting Depth | 10-3/4" | 10-3/4" |

| Cut Out Diameter | 13-7/8" | 13-7/8" |

| Sealed Enclosure Net Volume | 1.5ft3-2.0ft3 | 1.5ft3-2.0ft3 |

| Vented Enclosure Net Volume | 2.25ft3 | 2.25ft3 |

| Speaker Displacement | .24ft3 | .24ft3 |

| Volume Displacement (SD x XMAX) (in3) | 135.77 | 135.76 |

| Tuning Frequency | 34Hz | 34Hz |

Thunder 9512 Subwoofer Specifications |

||

| Model | T9512-44 | T9512-04 |

| Description | 12" Subwoofer | 12" Subwoofer |

| Impedance | Dual 4 Ω | 4 Ω |

| RMS Power (Watts) | 1,000 | 1,000 |

| Rec. RMS Amplifier Power (Watts) |

500 - 1,000 | 500 - 1,000 |

| Sensitivity | 91.00dB | 87.40dB |

| Voice Coil | 4" | 4" |

| Magnet Weight (oz.) | 260 | 260 |

| Mounting Depth | 9-3/4" | 9-3/4" |

| Cut Out Diameter | 11" | 11" |

| Sealed Enclosure Net Volume | 1.0ft3-1.5ft3 | 1.0ft3-1.5ft3 |

| Vented Enclosure Net Volume | 1.75ft3 | 1.75ft3 |

| Speaker Displacement | .19ft3 | .19ft3 |

| Volume Displacement (SD x XMAX) (in3) | 83.89 | 83.89 |

| Tuning Frequency | 35Hz | 35Hz |

Thunder 9510 Subwoofer Specifications |

||

| Model | T9510-44 | T9510-04 |

| Description | 10" Subwoofer | 10" Subwoofer |

| Impedance | Dual 4 Ω | 4 Ω |

| RMS Power (Watts) | 750 | 750 |

| Rec. RMS Amplifier Power (Watts) |

375 - 750 | 375 - 750 |

| Sensitivity | 87.48dB | 85.90dB |

| Voice Coil | 3.5" | 3.5" |

| Magnet Weight (oz.) | 195 | 195 |

| Mounting Depth | 9-5/16" | 9-5/16" |

| Cut Out Diameter | 9-3/16" | 9-3/16" |

| Sealed Enclosure Net Volume | .63ft3-1.25ft3 | .63ft3-1.25ft3 |

| Vented Enclosure Net Volume | 1.25ft3 | 1.25ft3 |

| Speaker Displacement | .14ft3 | .14ft3 |

| Volume Displacement (SD x XMAX) (in3) | 55.73 | 55.73 |

| Tuning Frequency | 37Hz | 37Hz |

|

|